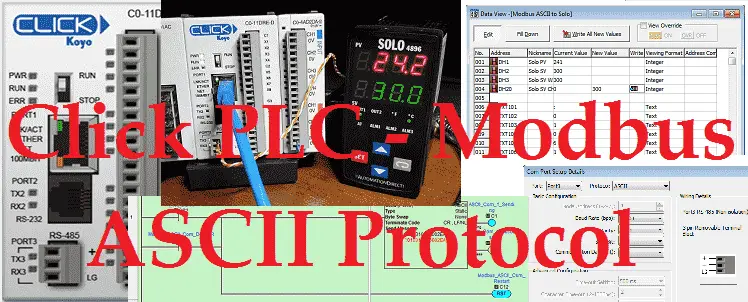

Click PLC Modbus ASCII Protocol Communication

We will now look at the click plc modbus ascii protocol. This communication will happen in PLC ladder logic and communicate through the serial port (RS485) to a Solo process temperature controller. Modbus ASCII will be the communication protocol. Modbus is a communication method used for transmitting information over serial lines between electronic devices. The … Read more