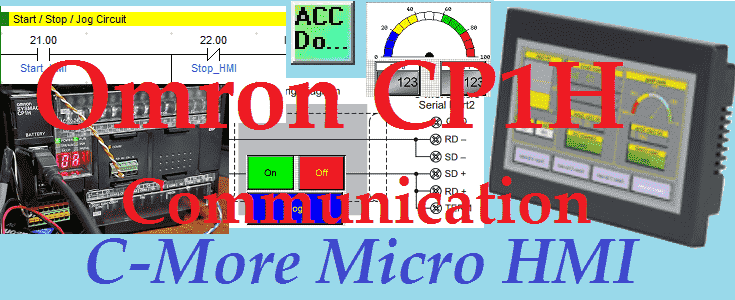

Omron CP1H to C-More Micro HMI Communication

The C-More Micro HMI panel is a series of human-machine interfaces (HMI) that provide a way for the operator to control and view your programmable logic controller. (PLC) The free C-more microprogramming software is user friendly and fully featured. C-more Micro panels can easily display text, graphics, and bitmaps to effectively communicate critical data to … Read more