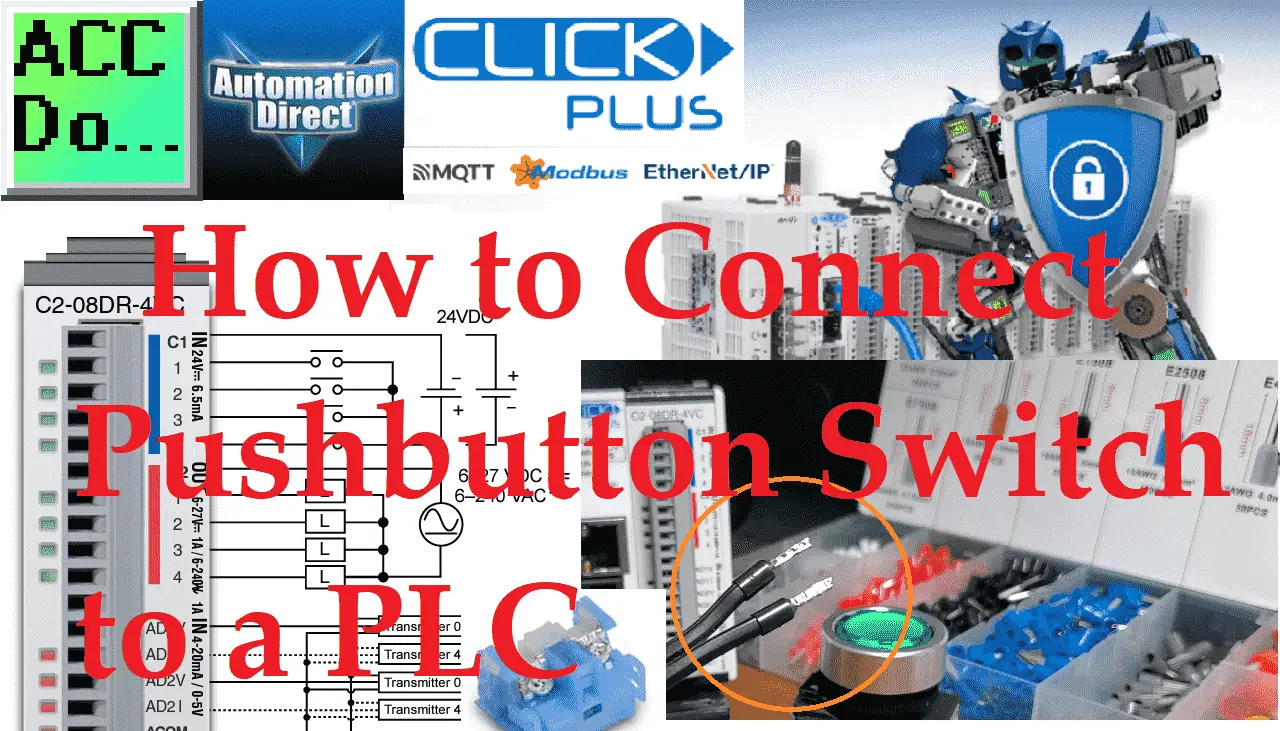

How to Connect Pushbutton Switch to PLC

We will connect a lighted pushbutton switch to a programmable logic controller (PLC). Using our Click PLUS PLC, we will be assembling, wiring, programming, and testing our pushbutton switch system. The Fuji Electric pushbutton, normally open (NC) contact, will be wired to the first PLC (X1) input. The LED light will connect to the Click … Read more