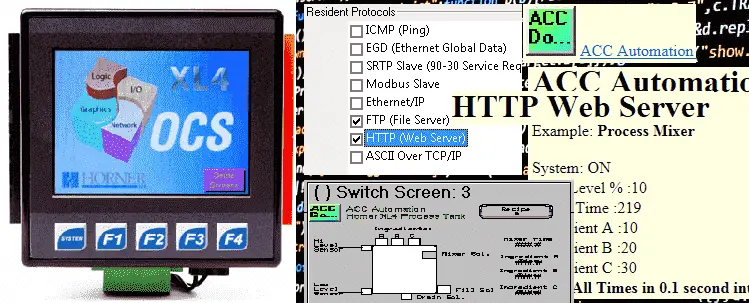

Horner XL4 HTTP Web Server – All In One

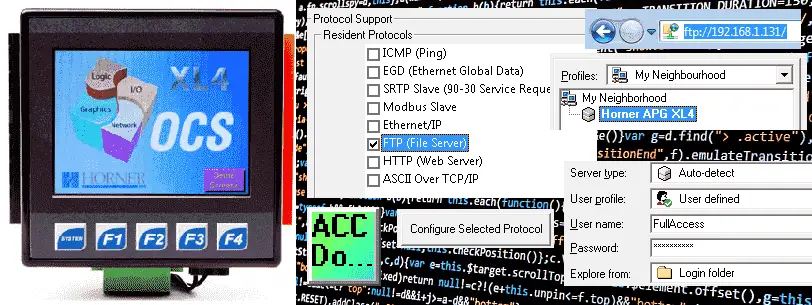

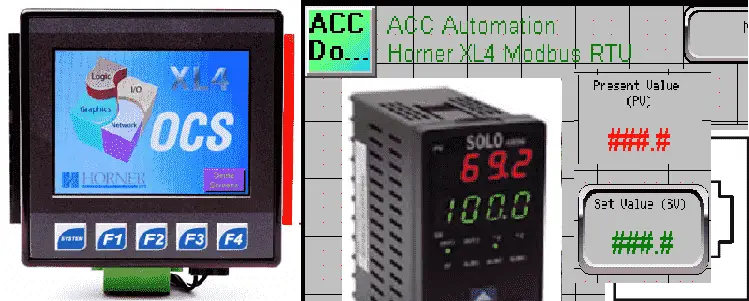

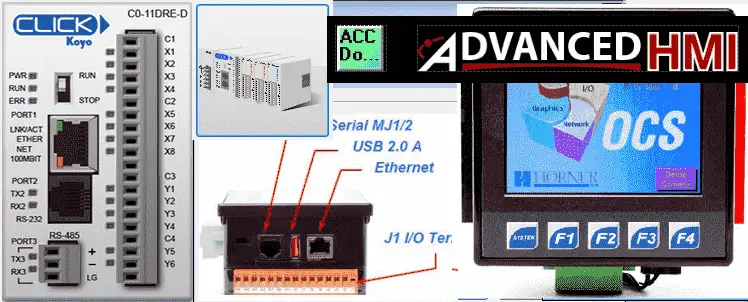

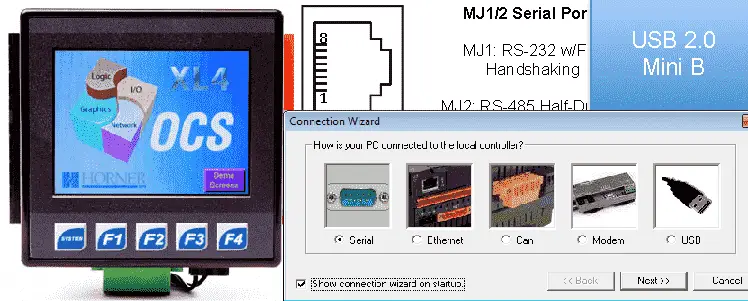

The Horner APG XL4 all in one controller through the Ethernet port can set up a HTTP server. This HTTP (Hypertext Transfer Protocol) server can be used for distributed and controlled information presented to and from the controller to the network. The server can have security for the information presented. We use HTML (Hypertext Mark-up … Read more