Creating a HMI Login Screen on AdvancedHMI

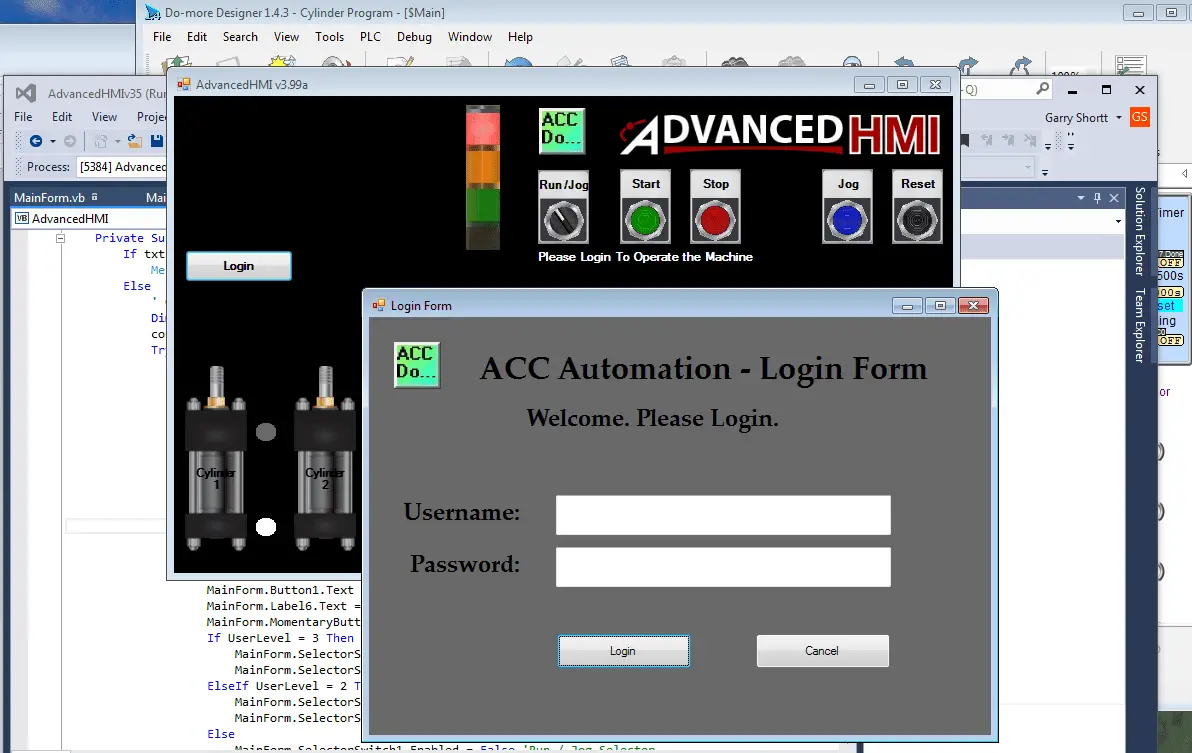

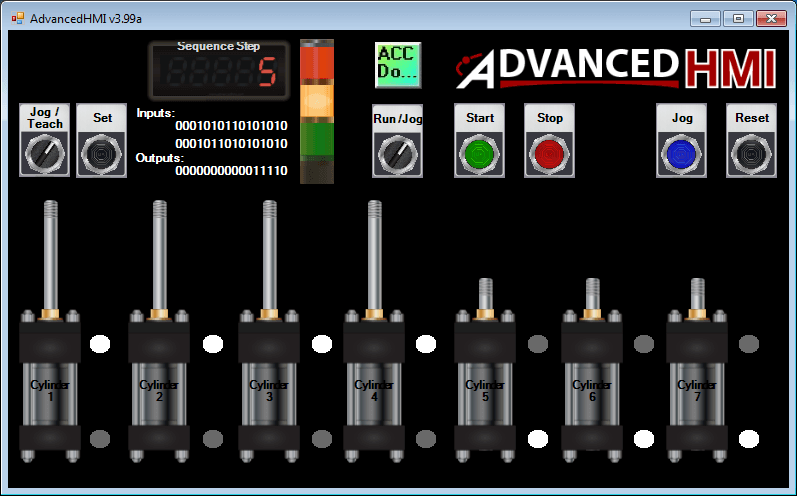

We will be creating an HMI (human machine interface) login screen for the cylinder program that we developed previously. BUILDING A PLC PROGRAM THAT YOU CAN BE PROUD OF – PART 6 Our program had a Run, Jog and Teach mode for the cylinders. Our user will login with a user name and password. Based … Read more