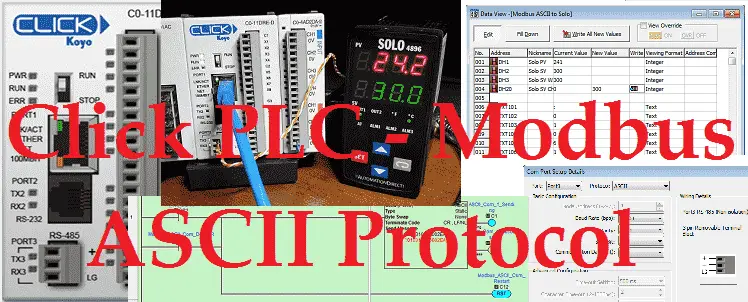

Mastering Click PLC Communication Modbus RS485!

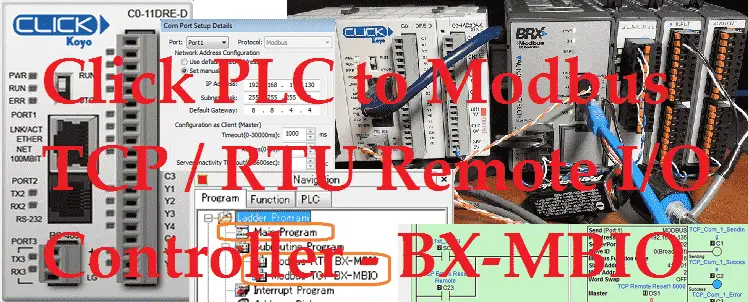

90% of industrial automation systems use Modbus for communication. This open standard protocol is used for everyday applications, including monitoring and controlling equipment such as PLCs (Programmable Logic Controllers), remote terminal units, sensors, and more in automation and process control environments. RS-485 typically utilizes twisted pair cables, which consist of two insulated copper wires twisted … Read more