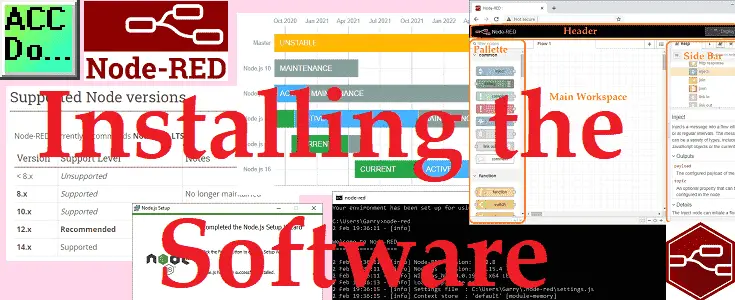

Node-RED Installing the Windows Software

We will now be installing the Node-RED software on our Windows 10 computer. Node-RED is a powerful and easy programming tool that will allow you to join together hardware devices, APIs (Application Programming Interface), and online services. This joining of information is part of the smart factory. Internet of Things (IoT), Industrial Internet of Things … Read more