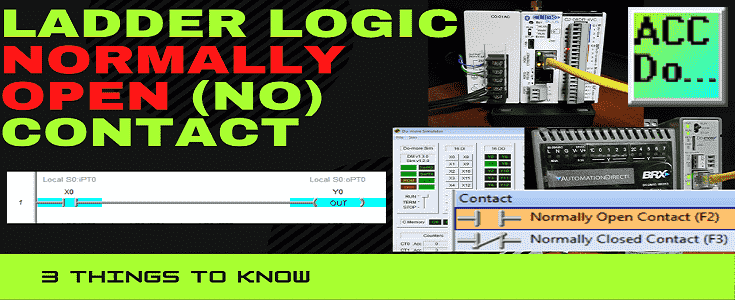

Ladder Logic (NO) Contact – 3 Things to Know

Normally open (NO) contacts or inputs in the PLC ladder logic program do not mean the same as a wired normally open switch. NO contacts on the ladder logic provide the logic condition for the rung to turn on the output. We will be looking at three things about the normally open (NO) contact on … Read more