Master PLC Sequencers: Boost Product Quality Like a Pro!

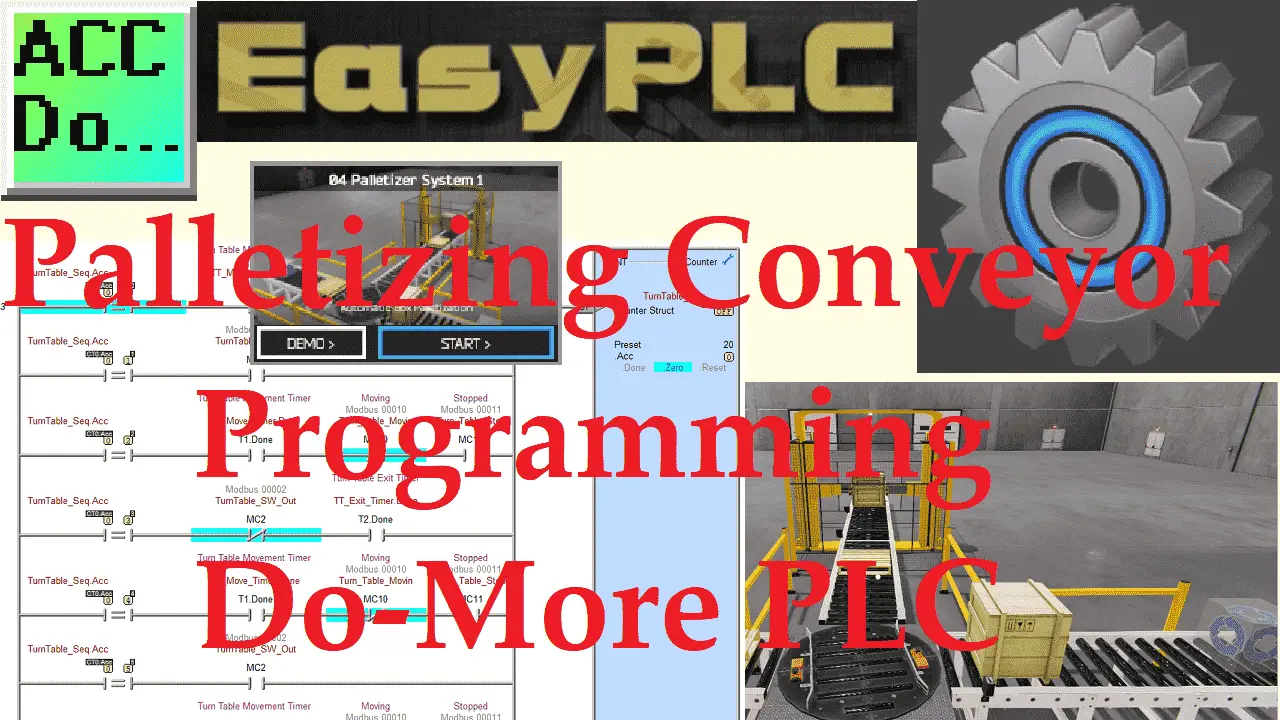

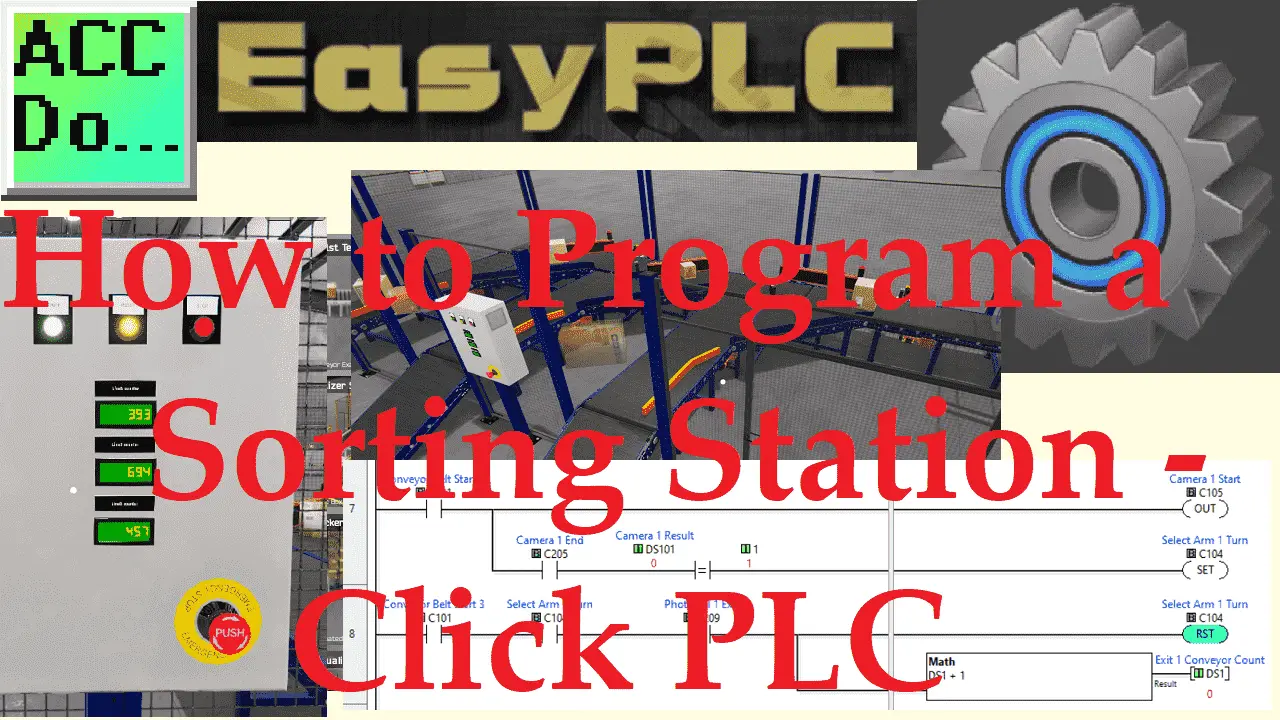

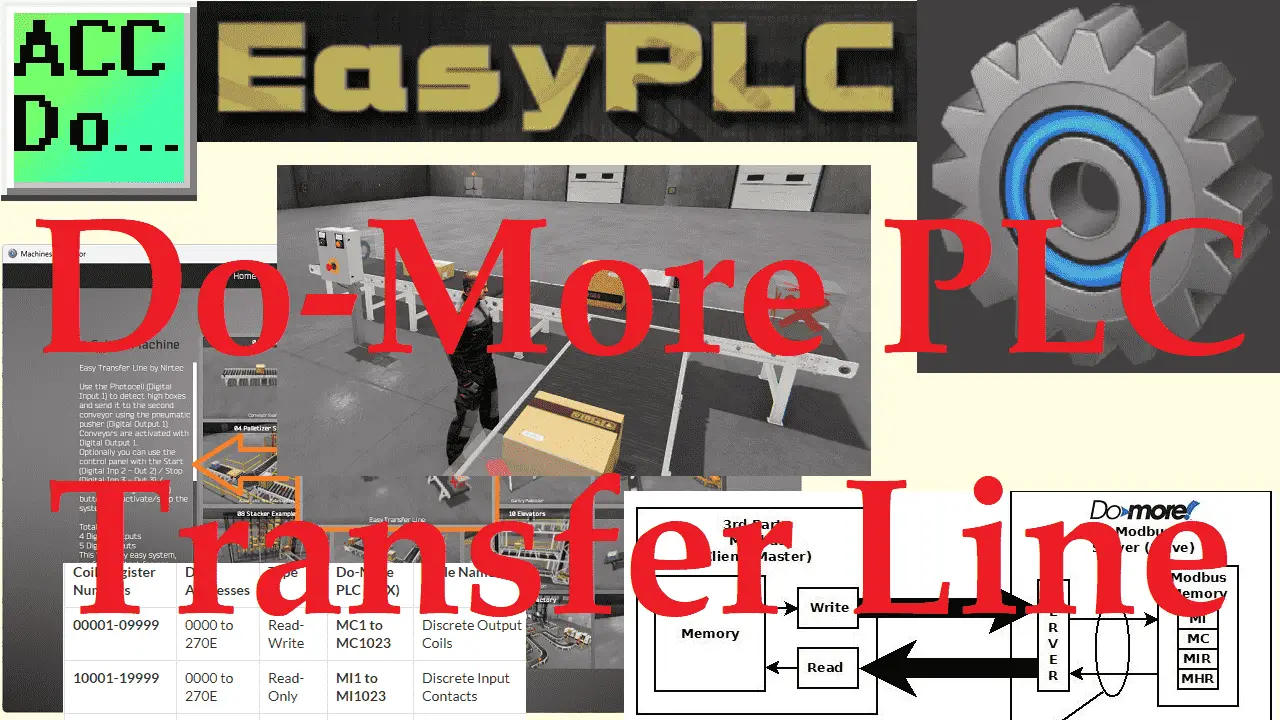

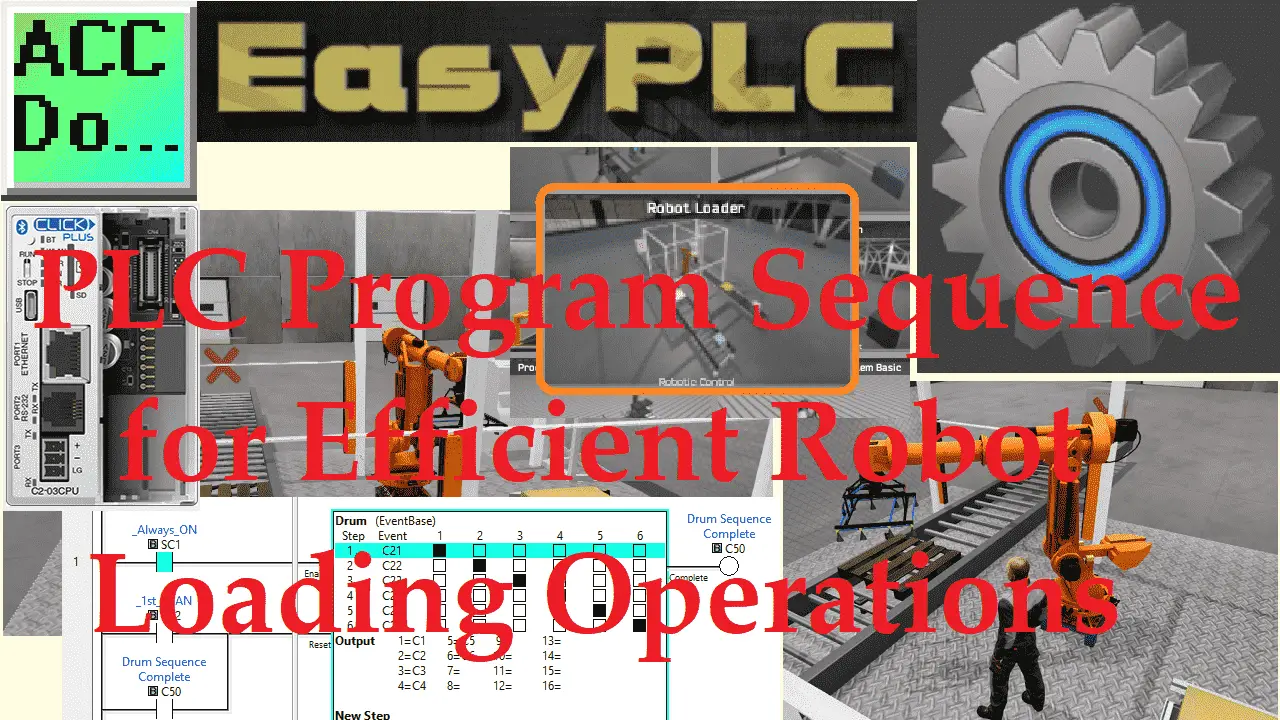

We will be demonstrating counter-sequencing logic on the Do-More PLC Simulator and EasyPLC. EasyPLC software suite includes a machine simulator named Machine Simulator (MS). It has a variety of machines that can be programmed and customized. One of these machines is the body car quality verification machine, which utilizes a camera and a collaborative robot … Read more