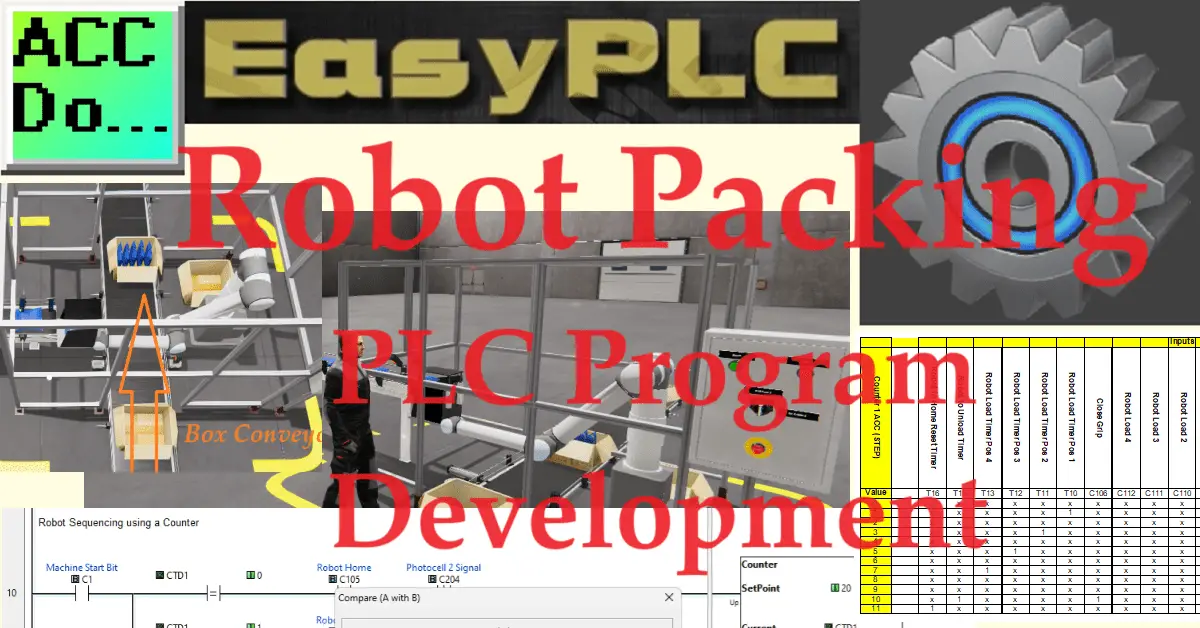

Robot Packing PLC Program Development

The Machine Simulator (MS) is a valuable component of the EasyPLC software suite. It offers a range of built-in machines, including the robot packing machine, which effectively demonstrates various programming techniques. We will use the Click PLC programming software to showcase a sequencer application for this example. In this scenario, the robot is tasked with … Read more