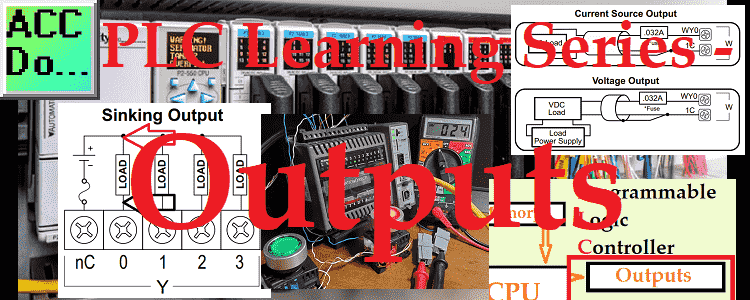

PLC Learning Series – What are Outputs?

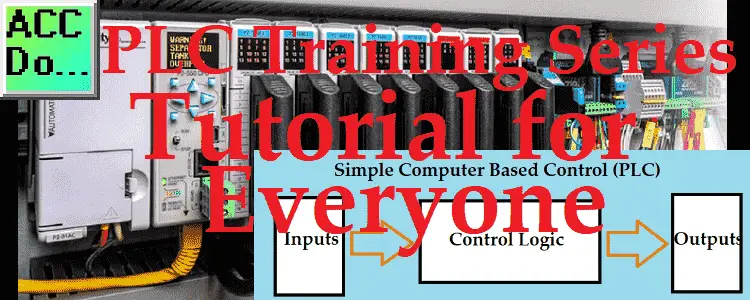

PLC outputs are the next component of our PLC block diagram. The PLC program will control the outputs of the PLC. Controlling outputs is one way to get the inputs to change. We will be looking at digital and analog outputs that can be wired to the programmable logic controller. PLC troubleshooting outputs will also … Read more