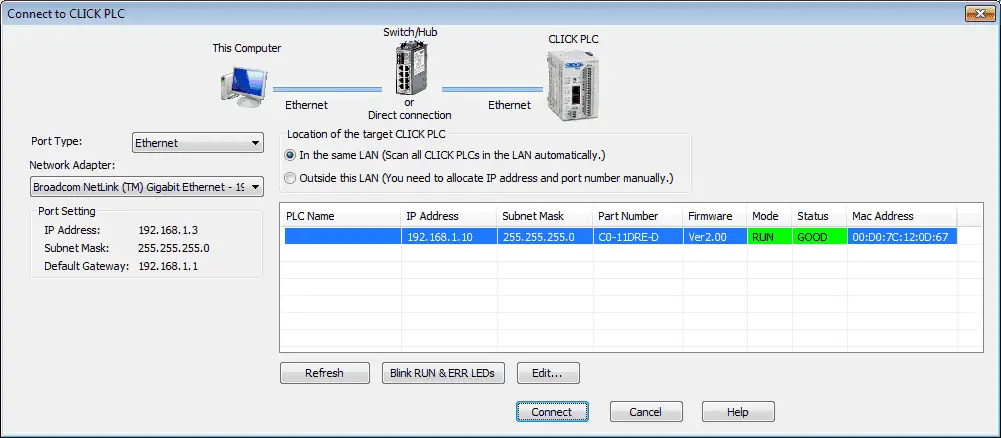

Click PLC Establish Communication

So far in this series, we have discussed the Click PLC System Hardware (Video) and Installed the Software (Video). Today we will be establishing PC to PLC communications. This will allow us to program, edit or alter the way in which our Click PLC will function.