Stop Struggling! Master Productivity 1000 PLC Debugging Tools

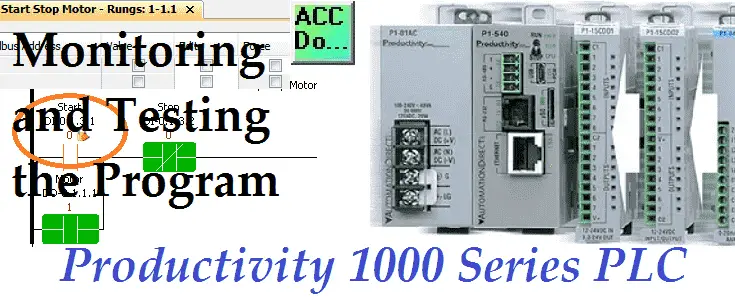

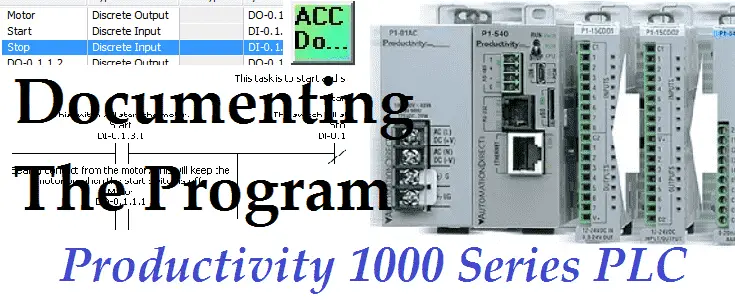

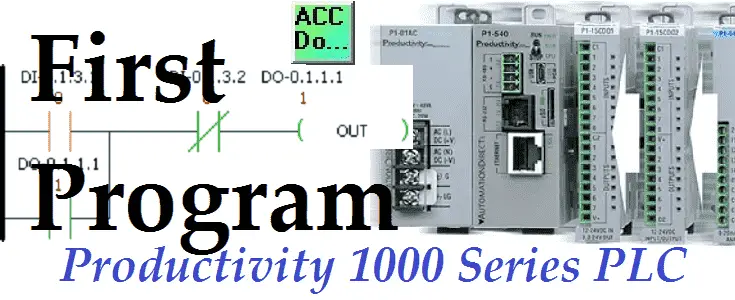

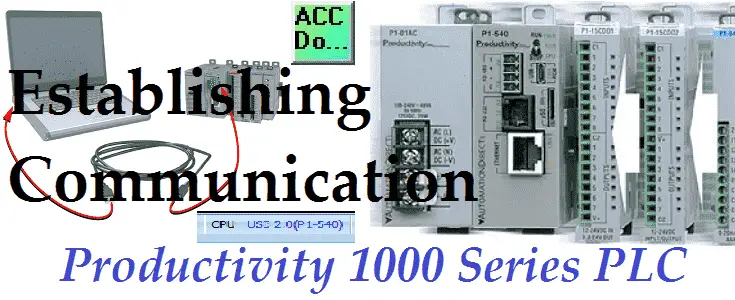

We will now look at monitoring and testing our productivity program. The Productivity Suite Software provides tools for us to monitor and test our programs. Last time we used Tag Names and Details, Task Names and Descriptions, Rung Comments, and Instruction comments to document our first program and transferred this to our connected Productivity 1000 … Read more