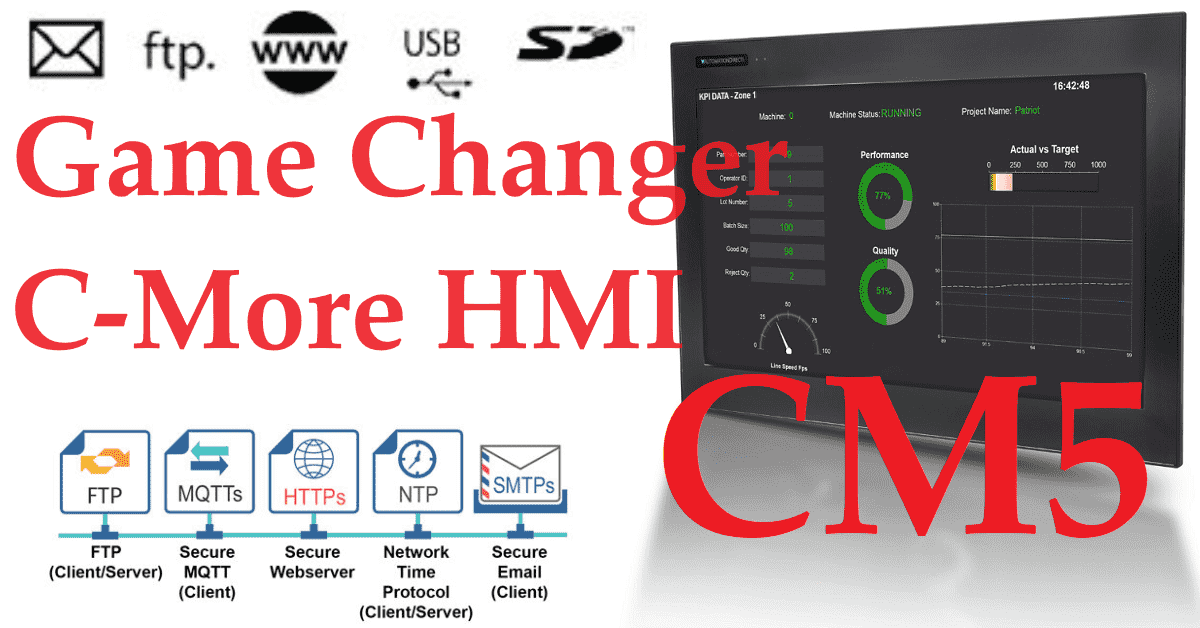

Latest C-More CM5 HMI Game Changer

The CM5 industrial HMI from the C-more series is a competent and versatile human-machine interface packed with several advanced features and functionalities not typically found in an operator panel. This latest addition to the C-more series has been specifically designed to cater to the requirements of industrial automation applications, providing a dependable and user-friendly interface … Read more