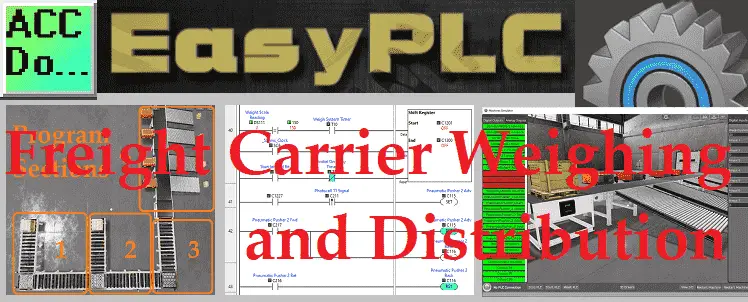

Freight Carrier Weighing & Distribution EasyPLC

The freight carrier weighing and distribution will demonstrate sequencing and shift registers on the EasyPLC machine simulator. The product comes in two different ways and must be organized, weighed, and delivered on the right output ramp. This will be based on the weight of the product. The EasyPLC simulator freight carrier will show you how … Read more