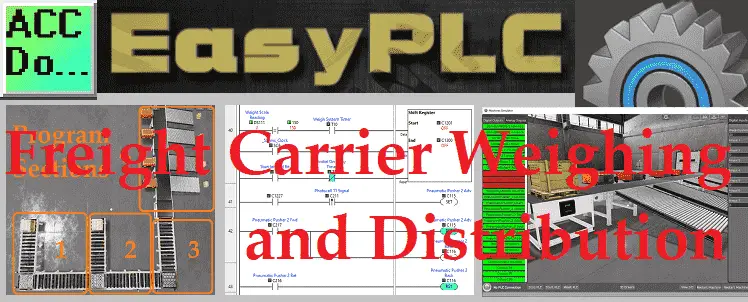

EasyPLC Machine Editor – Design a Simulation

EasyPLC comes with many prebuilt machines for you to develop the programming logic. These can be modified, or new custom machines can be programmed using the machine editor. The machine editor comes as a standard feature of the EasyPLC Software Suite. The EasyPLC Machines Simulator editor is an easy-to-use tool enabling you to create easy, … Read more